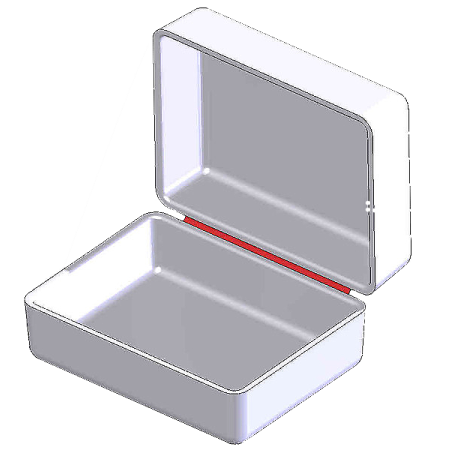

Use our expertise in designing for Stereolithography

Design for Manufacturing Services

Our design team can optimize CAD models for functionality and cost. Companies can collaborate with us to enhance designs or quickly implement changes before manufacturing parts.