Get A Quote for 3D Modelling and FEA Services

♦ Reliable and affordable DFM services ♦ Manufacturing Support

No products in the cart.

Upload a file, review the instant quote and

get your parts made with the fastest and

most efficient 3D printing network

DigiPro 3D offers industrial 3D printing services for iterative components, prototyping, end-use production parts. We

specialize in 4 additive manufacturing processes, 75+ materials, and several finishing add-ons. We are your one-stop-shop

for reliable and precise 3D printing at an affordable cost, delivering with a lead time as low as 2 days.

In Fused Deposition Modelling, semi-solid plastic filament is squeezed through hotend and then deposited in pre-defined path layers by layer to create a form.

Access a large FDM facility ready for prototyping or batch production.

Stereolithography (SLA) technology uses light-reactive thermoset materials called “resin”, then using a light

source to cure liquid resin into hardened plastic.

Get SLA 3D printing services with click of a button.

Selective laser sintering (SLS) technology that uses a high power

laser on a sintered small particles of polymer powder to fuse them locally into a solid structure.

Print your parts via efficient and high-performance SLS 3D printing services.

Direct metal laser sintering (DMLS) technology processes finely powdered metal then heats particles enough so that their surfaces weld together to create a form.

Use our partnered network to 3D print metal parts.

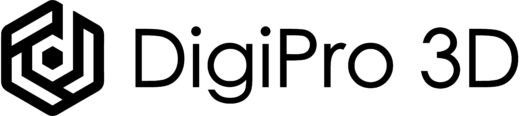

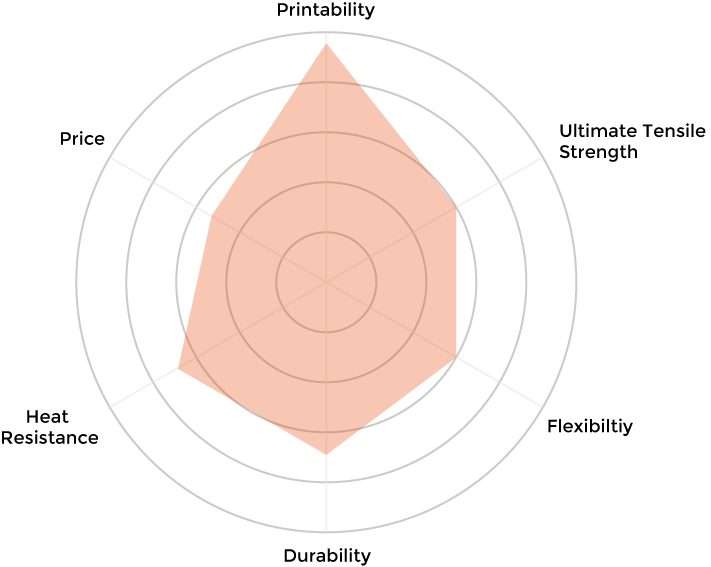

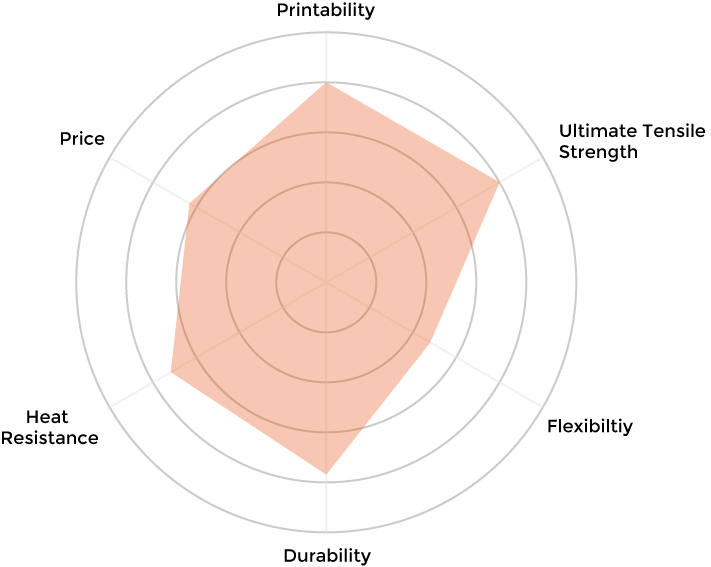

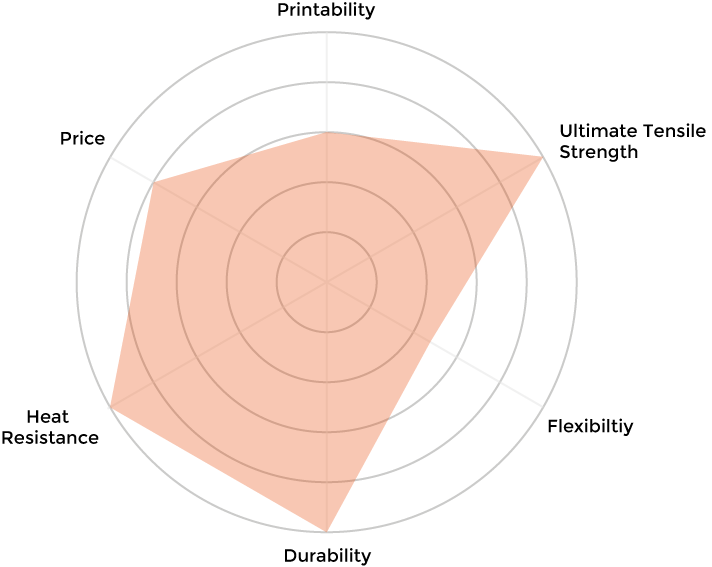

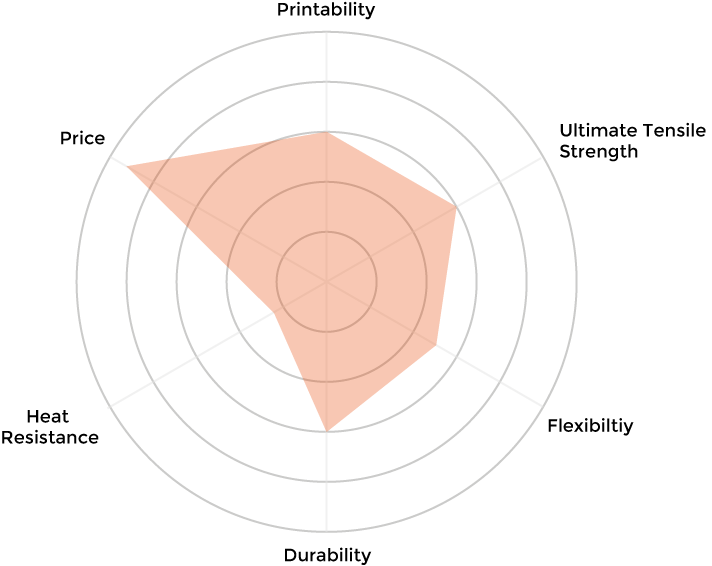

PLA is the go-to material due to its ease of printing, dimensional accuracy, and low cost. It is rigid and strong but brittle thus it is used in low-stress applications.

Temperature: 190-220 °C

No special hot-end required

Temperature: 45-60 °C

Enclosure not required

Painter’s tape

Glue stick

Part cooling fan required

Fan Speed: 40% - 100%

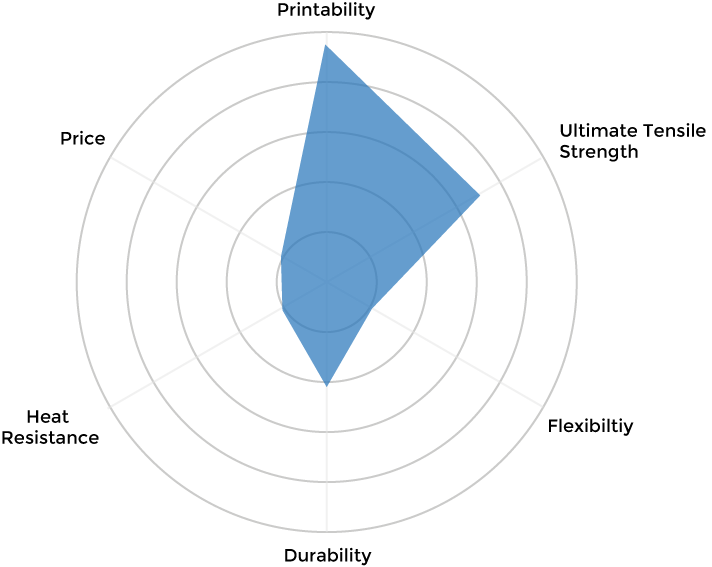

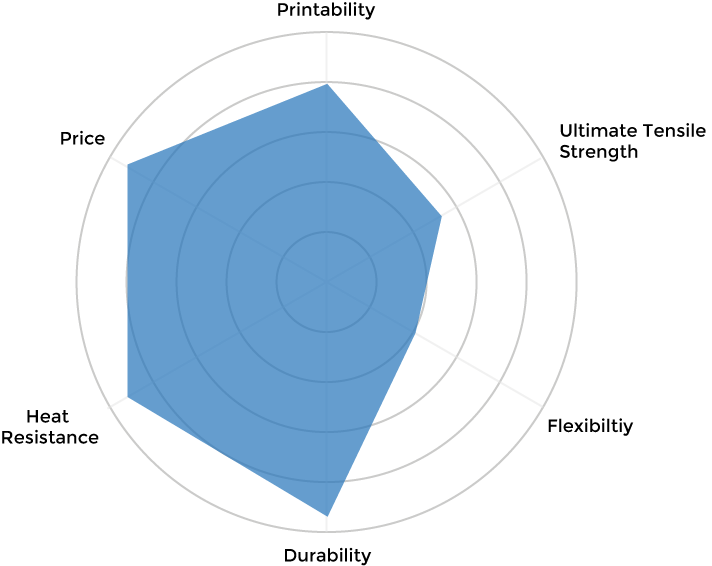

ABS filament is the most commonly used 3D printing plastic. ABS is affordable, strong, lightweight heat resistant so it’s used in a medium stress scenario.

Temperature: 220-250 °C

No special hot-end required

Temperature: 95-110 °C

Enclosure recommended

Kapton Tape

ABS Slurry

Part cooling fan

not required

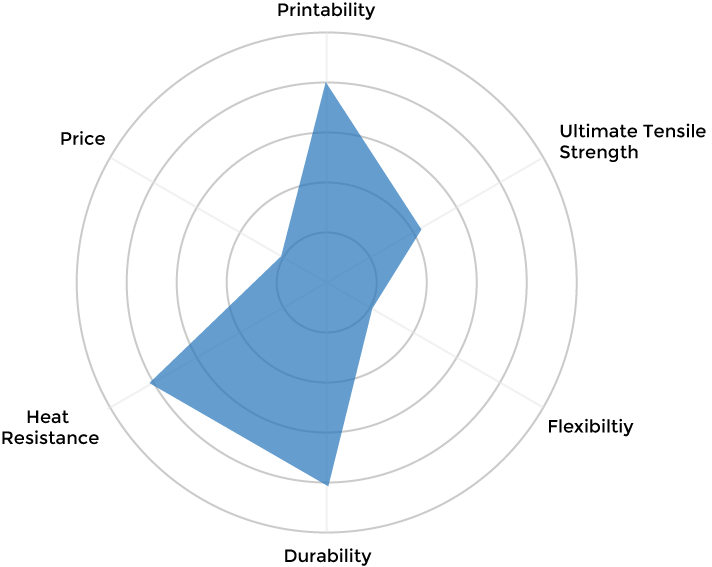

PETG is an all-rounder material characterized in-between PLA and ABS. It has higher strength but less rigidity, this material possesses some interesting properties like weather resistance and food grade.

Temperature: 230-250 °C

No special hot-end required

Temperature: 75-90 °C

Enclosure not required

Painter’s tape

Glue stick

Part cooling fan required

Fan Speed: 70%-100%

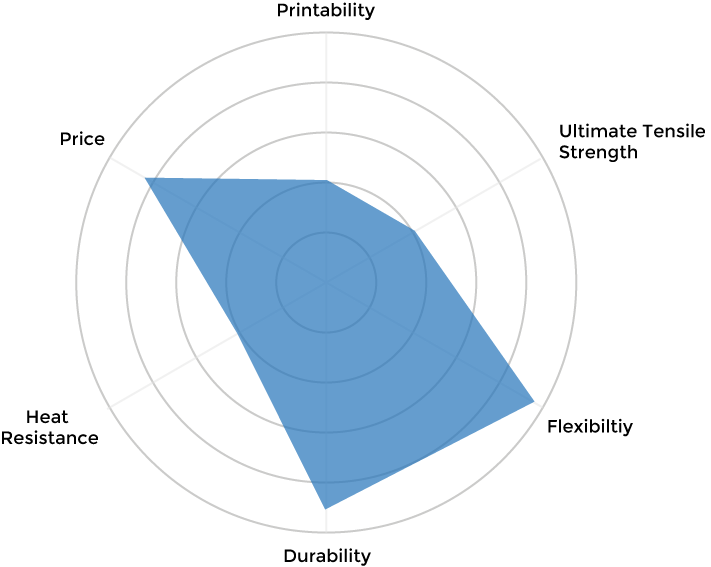

Flexibles are Soft and stretchable materials that can withstand the beating that neither ABS nor PLA can tolerate. Due to these properties, they are very difficult to print. They are also resistant to a chemical reactions, UV exposure and heat.

Temperature: 225-240 °C

Direct drive extruder recommended

Temperature: 45-60 °C

Enclosure not required

Painter’s tape

PEI

Part cooling fan required

Fan Speed: 70%-100%

The carbon fibre material is extremely stiff and rigid. It is perfect for printing strong and durable parts.

Temperature: 220-250 °C

Wear resistant nozzle recommended

Temperature: 70-80 °C

Enclosure not required

Kapton Tape

PEI

Part cooling fan required

Fan Speed: 70% - 100%

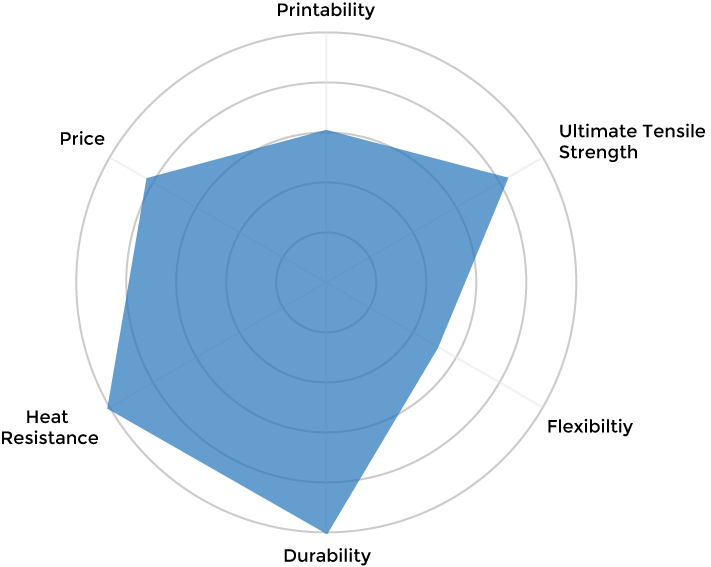

Polycarbonate is one of the strongest 3D printing materials out there, it’s known for impact and heat resistance. It is susceptible to moisture and requires a very high temperature for printing.

Temperature: 260-310 °C

All metal hot-end required

Temperature: 120-150 °C

Enclosure recommended

Commercial adhesive

PEI

Part cooling fan

not required

Standard resin is an easy to print, general purpose photopolymer resin. It prints faster than other materials making it ideal for initial prototypes and rapid iterations. Parts printed with standard resin have smooth finish and higher accuracy. This material retain its colour and finish due to its excellent UV resistance.

9 Seconds / Layer

Water

15 °C

ABS-like resin has high precision, good strength, and low creep. This material is great for concept modelling and functional prototyping. Parts printed with ABS resin exhibit High hardness and toughness, impact resistance.

12 Seconds / Layer

Water

Isopropyl alcohol

22 °C

Tough resin is one of the strongest and stiffest materials. Parts printed with tough resin can handle compression, stretching, bending, and impacts without breaking. This material has fewer brittle failures and better performance at elevated temperatures.

16 Seconds / Layer

Water

25 °C

The low ash content after burnout of the part and low expansion makes castable resin easy to cast metal or plastic parts. Castable resin offers high strength and stiffness, making it highly capable of printing ultrafine details. It is suitable for jewellery and other small and intricate components.

24 Seconds / Layer

Water

Isopropyl alcohol

25 °C

♦ QUOTATION WITHIN MINUTES ♦ QUALITY AND LEAD TIME COMMITMENT

Removal of the support structure (standard and dissolvable) |

Sanding to improve surface finish |

Enhance aesthetics through priming and painting in the desired colour |

Cold welding large ABS parts, gap filling and vapour smoothing |

Epoxy Coating for added strength and finish |

UV curing printed part and support structure removal |

Dry and wet sanding for support nib removal and finishing |

Spray painting a coat for improving finish on complex geometries and UV protection. |

Sifting SLA 3D prints |

Media blasting or media tumbling for smoother surface finish |

Spray painting or coating to achieve desired colour and finish |

Electroplating to make build parts rigid, lightweight and give them a metallic look. |

Depowder DMLS part to remove trapped powder |

Heat treatment in an inert or vacuum atmosphere to relieve the internal stresses and improve the mechanical properties |

Machining of build to achieve finer tolerances |

Shot blasting or electropolishing to improve the surface finish |

We offer 3D printing, CNC machining, Injection moulding and sheet metal fabrication services. Our team also specializes in design for manufacturing services. Contact us for your manufacturing and 3D modelling requirements.

3D printing is a manufacturing process to create three-dimensional models directly from digital blueprints. Usually, it utilizes successive layer addition techniques called “Additive Manufacturing”. Product is created by simple horizontal layer by layer addition of material from bottom to the top.

DigiPro 3D currently offers all engineering materials for NC manufacturing and injection moulding. In the case of 3D printing, we can deliver the 3D print with ABS, PLA, PETG, PC, flexible etc. If your order requires rare or irregular materials, include them in the details section of the order page.

You can opt for various post-processing methods such as sanding, painting, acetone wash, coating, smoothing etc. If you have any specific post-processing requirements, please update them in the order form.

You can order parts through a very simple three-step process. Click on the Get a Quote button and upload CAD files, you will receive a quote for your requirements, approve your quote and make a payment as confirmation. You will receive the tracking id as we ship the order. All parts go through quality control, to ensure that parts are manufactured as per requirement.

DigiPro 3D can help you by providing designing services as well. Describe your requirements in the order form, and a Solution Engineer will get in touch with you.

DigiPro 3D takes the necessary measures to ensure the protection of your IP. We use secure connections for all our customer and manufacturing partner file transfers as well as data storage. For further assurance, customers can sign an NDA here.

Yes, DigiPro 3D has a dedicated manufacturing solutions team to attend to such queries. Just fill up our custom manufacturing form and the relevant solution engineer will contact you.

Lead-time varies based on the material ordered and the process selected. Our orders are customized for you which means that their production times will vary. An estimated ship date can be given to you by your respective Solution Engineer. We do our best to get your orders to you as quickly as possible. Once we’ve shipped your order, package transit time will depend on the shipping option and destination.

Get a design for manufacturability feedback from our experienced team of engineers to optimize the design for better strength and fast turnaround.

Choose from a range of thermoplastics, resins and metal powders to 3D print that suits your application.

To further improve mechanical properties and aesthetics, we offer post-processing options such as coating, plating, painting, machining and heat treatment.

Whether one-time prototyping or a production run we’ve got you covered. With our in house 3D printing factory, your product is dispatched within a day. We offer same-day delivery for 3D printing in Pune.

We deliver parts with industry-leading precision and surface finish due to our high-grade manufacturing machines and a dedicated staff of 3D printing technicians. If required, we provide material certification, finish certifications and inspection reports.

3D Modelling

We offer production-ready design with the final design specs, 3D renderings, and measurements needed to manufacture it. For 3D modelling services in Pune, we offer a personal consultation.

Topology Optimization

Improve your components and systems for Optimum structural, thermal or fluidic properties using our domain expertise. We offer training for your team on properties and capabilities of commercial software.

Generative Shape Design

With AI-driven generative shape design services develop high quality, low-cost designs that perform better in the real world. We provide design optimisation for specific material and manufacturing processes, based on your requirements and constraints.

Finite Element Analysis (FEA)

Analyze the impact of structural, vibration, thermal and fluidic loads to predict how your system will perform in the real world. Our finite element analysis services deliver FEA solutions with precise load and constraint representation.

♦ Reliable and affordable DFM services ♦ Manufacturing Support